Stringed instruments need to be tuned before playing, if they are expected to be musical. The following is adapted from a recent wikipedia page.

A variety of methods are used to tune different stringed instruments. Most change the pitch produced when the string is played by adjusting the tension of the strings.

A tuning peg in a pegbox is common in violins (of various sizes, such as Violas, Cellos, etc., but Bass Viols typically use geared machine heads) and many older instrument types. A peg has a grip or knob on it to allow it to be turned. A tuning pin is a tuning peg with a detachable grip, called a tuning lever or wrench. The socket on the tuning lever fits over the pin and allows it to be turned. Tuning pins are used on instruments where there is no space for a knob on each string, such as pianos and harps. Turning the peg or pin tightens or loosens the string. Some tuning pegs and pins are tapered, some threaded.

Other tuning systems include screw-and-lever tuners, geared tuners, and the konso friction tuning system (using braided leather rings).

A machine head (also referred to as a tuning machine, tuner, or gear head) is the geared apparatus typically used for tuning mandolins, guitars, double basses and others, and are usually located on the instrument’s headstock.

Construction and action

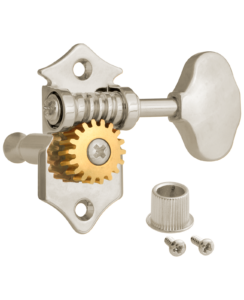

Traditionally, a single machine head consists of a cylinder or capstan, mounted at the center of a pinion gear, a knob or “button” and a worm gear that links them. The capstan has a hole through the far end from the gear, and the string is made to go through that hole, and is wrapped around the capstan. To complete the string installation, the string is tightened by turning the capstan using the tuning knob. The worm gear ensures that the capstan cannot turn without a movement on the knob; it also allows precise tuning.

Banjos usually employ a different mechanism using planetary gears – in this case, the knob and the capstan both rotate on the same axis. A few guitars (e.g. the original Gibson Firebird, early Gibson basses and Mario Maccaferri’s plastic instruments) have used this design.

Varieties

Several kinds of machine head apparatus exist:

- on classical guitars (with nylon strings), the worm gears are generally exposed; the strings are wound on the pins inside grooves in the head;

- on modern steel-string guitars, including “folk” acoustic and electric guitars, the worm gears are generally placed in individual sealed enclosures with permanent lubrication, although budget models may have exposed gears fixed on plates housing a row of gears. (The reverse of the machine heads on a “folk” steel-string acoustic guitar.)

- Vintage and vintage-reproduction guitars frequently have individual open-gear tuners, enclosed tuners not having become common until after WWII.

- Several machine head placements are possible, depending on the shape of the headstock:

- rectangular head, 2 rows of 3 pins (or 6 pins for 12-string guitars): found on most “Folk” and “Jazz” guitars and on Gibson Les Paul guitars;

- a single diagonal row of 6 pins: found on Fender Telecaster and Stratocaster guitars;

- one diagonal row of four pins and one diagonal row of two pins: found on Music Man guitars;

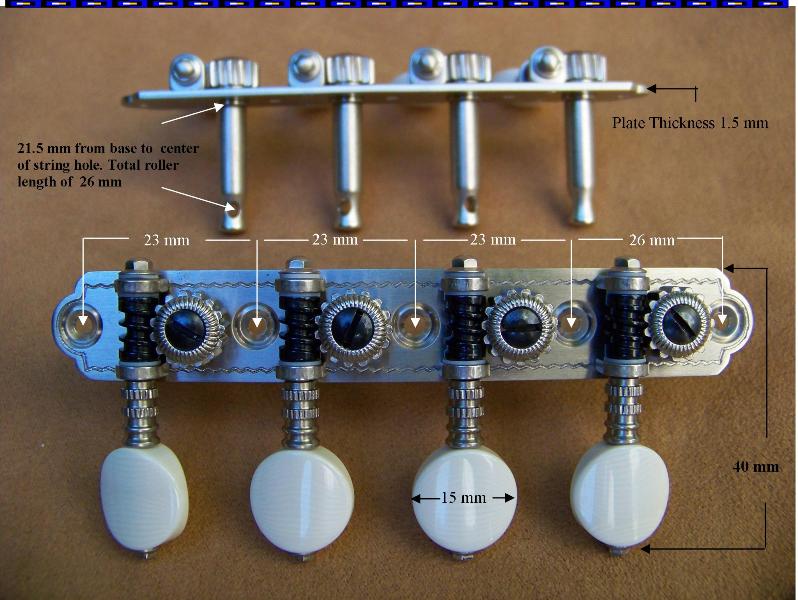

- on bass guitars, where string tension is extremely high, larger, heavier-duty machine heads than those used on guitars are used. Bass tuners generally feature larger knobs than guitar tuners as well; often these are distinctively shaped, and known as “elephant ears”. Gear ratios of 20:1 are used often. Exposed gears are much more common in premium bass guitars than in six-string non-bass instruments. (Martin EB18 bass guitar headstock, showing Martin open-type machine heads, and typical Double Bass style tuners.)

On some guitars, such as those with Floyd Rose bridge, string tuning may be also conducted using microtuning tuners incorporated into the guitar bridge.

Likewise, ‘headless’ guitars and basses, notably those designed by Steinberger and their licensed imitations, such as the Hohner Jack Bass, and unlicensed imitations such as the Washburn Bantam, have the machine heads at the body end. Steinbergers and Hohners require specialist double-ball end strings, whereas the Washburn Bantam can take regular strings.

Gear Ratios

Presently, most worm-gear tuners provide a gear ratio of 14:1. In older designs, 12:1 was common, and lower ratios as well. Lower ratios allow a replacement string to be brought more quickly up to pitch, though with less precision for fine-tuning. Lower ratios are also more forgiving of imperfect machining, and of factors that might compromise the gear surfaces (corrosion, grit, poor lubrication).

As increased precision of milling became more cost-effective, higher ratios appeared on the market, with 14:1 being the modern standard, trading accuracy against slower initial string winding. More recently, versions with an 18:1 gear ratio are available (particularly from Grover), and the Gotoh 510 offers 21:1.

Locking tuners

The term “locking tuners” has two meanings. Presently, it refers to some sort of mechanism in the string peg (usually a cam or screw) that locks the string in place, preventing slippage. With the popular increase of extreme vibrato-arm usage in the 1980s, several manufacturers introduced a modified design, commonly called locking machine heads, where the individual tuner has an additional mechanism to lock the string in place and stabilize tuning, primarily intended for musicians who make regular use of the vibrato. Some designs increase string breakage at the point they grip the string.

The term “locking” is much older, possibly originating with Grover, and refers to an “anti-backlash” design of the gears, which greatly reduced the slippage of the basic worm-and-gear system. The gear’s teeth are shaped to lock into those of the worm, with the string tension insufficient to overcome the friction between the gears. Such a design is called self-locking. Grover Rotomatics and similar designs from other manufacturers are rightly called “locking tuners”.

Manufacturers

There are several brand-name manufacturers of tuners.

- Alessi (the “Platinum Standard” — the Ferrari, because of the quality, the hand-building, and the $$$$price)

- Rubners (the Audi)

- Waverly ( “Gold Standard” of mass produced – the Camaro) (Owned by StewMac)

- Schaller (Gold-plated standard — the quality difference is huge and obvious once you look below the surface. They are good but never excellent. The Honda Accord/Toyota Camry.)

- Gotoh (Gold-plated standard — the quality difference is huge and obvious once you look below the surface. They are good but never excellent. The Honda Accord/Toyota Camry.)

- Grover (Gold-plated standard — the quality difference is huge and obvious once you look below the surface. They are good but never excellent. The Honda Accord/Toyota Camry.)

- (Stew-Mac) Golden Age (?? not highly regarded…, especially considering the price)

Tuner Maintenance

While we’re here, I came across this little nugget about tuner maintenance: https://www.lutherie.net/tuner.maintenance.html